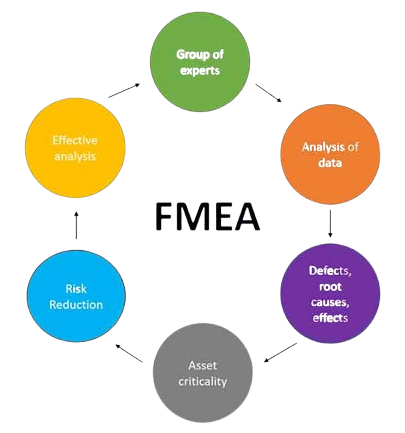

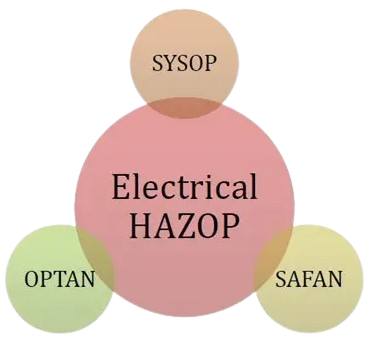

Hazard Identification and Operability Analysis utilizing different techniques is critical components of process safety services. Hazard identification involves systematically identifying potential hazards in a process or system to ensure safe design and Operation. Operability Analysis focus on identifying operational issues that could impact efficiency, reliability, and overall performance.

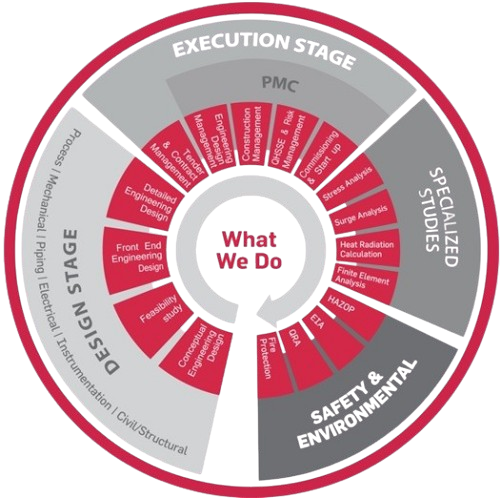

Benchmark Consulting Engineering L.L.C has extensive experience applying these techniques in offshore and onshore industries, including continuous and batch processes, large-scale projects, and small package units in compliance with international standards and project-specific or client-specific needs.