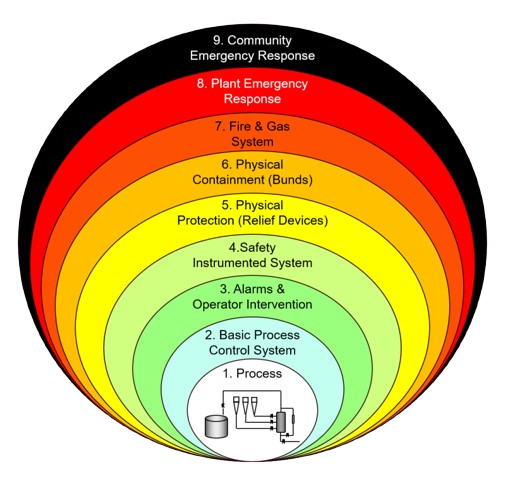

Functional safety refers to the concept of ensuring that a system or equipment operates in a safe manner, particularly when it comes to managing hazards and preventing accidents that could result in harm to people, damage to the environment, or loss of assets.

Benchmark Consulting Engineering L.L.C provide specialized services for Functional Safety that involve conducting the following: